ENGINEERING CONSULTATION

Dyna is engaged by Oil & Gas Companies to advise on specific projects or client requirements, including upstream and downstream operations. Among others, Dyna representatives advise on field development, platform fabrication, refinery construction and modernization, crude oil and petroleum products trading, tank farm development, electrical equipment and equipment. requirements for instrumentation, etc. We also offer consulting services for the following operations:

Team representatives at Dyna were tasked with overseeing the construction, commissioning, operation and decommissioning of Malaysia’s first FPSO (Floating Production, Storage and Offloading System).

Dyna O&M has completed the construction of protective enclosures and topsides for major oil companies, namely Shell, ExxonMobil and PETRONAS.

One of our areas of expertise is the chartering and management of offshore supply vessels ranging from barges to crew boats, work and supply vessels, anchor handling tugs and pipe-lay barges.

Project management consulting.

CORROSION UNDER INSULATION (CUI) MANAGEMENT

SMART COATING

Dyna O&M is a protective and marine coating supplier offering a full range of high performance coating technologies for corrosion control. A typical piping coating system is not able to withstand the cycling of heat and cold under the insulation. No need to fear, Dyna Segmen can provide unrivaled service and coating specification support to meet our customers’ coating needs with our smart coatings.O&

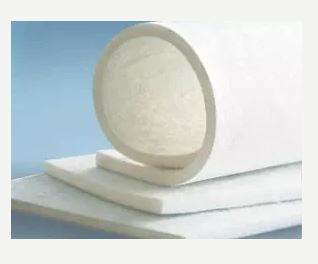

In addition to the usual insulation material (rock wool, glass wool, perlite, etc.), Dyna can also provide aerogels. Aerogels are the lightest solid materials in the world, containing up to 99.98% air by volume. Airgel are super insulating silica aerogels that exhibit the lowest thermal conductivity of any known solid insulation material and the lowest density construction material ever developed for hot and cold insulation. The hydrophobic properties of the airgel insulating coating can prevent water penetration in the event of liner damage and thus reduce the CUI.

ADVANCED INSULATION MATERIAL

NON-DESTRUCTIVE TESTS

Non-destructive testing (NDT) are analytical methods used in science and industry to assess the properties of a material, component or system without causing damage. Since NDT does not permanently change the item under test, it is a very valuable method to save money and time in product evaluation, troubleshooting, and research. Common non-destructive testing methods include ultrasonic, magnetic particle, penetration, radiographic and eddy current testing. NDT is a widely used tool in engineering.

It is a technique used to detect surface fracture defects in any non-porous material. Liquid penetrant is applied to the surface and is drawn into defects by capillary action. After a predetermined holding time, the excess penetrant is removed and a developer is developed to remove the penetrant from the defects. Then a visual inspection is performed. Visible and fluorescent liquid permeability testing is a non-destructive method of detecting open discontinuities on surfaces of solid and essentially non-porous materials, whether black or colored.

Advanced phonon testing includes global test methods, in particular AET (Acoustic Emissions), in the RBI (Risk Based Inspection) program to detect hidden corrosion under insulation.

LIST OF NDT SERVICES

• Column Scanning

• Tank Bottom Scanning

• Pipe Plant Shop Inspection

• Radiometric Inspection Technique

• Welding Inspection

• Stress Relief (SR)

• Non-Destructive Inspection

• Surface Coating Assessment and Scope of Work

• Pipe

Coating Break Detection • Sandblasting and Paint Coating Inspection

• Supervision blasting and painting

• Expanded phonon testing (inclusion of AET in RBI)

DRONE INSPECTION

Dyna O&M Sdn Bhd has expanded its technical capabilities with the addition of a Remote Air Operated Device (RAOV) to its service offerings. Our technical service includes:

• Supply of labor for remote inspection.

• ROAV delivery

The current challenges our clients face when inspecting hard-to-reach areas have pushed us towards finding solutions that are cost-effective and time-efficient. Prior to the advent of unmanned aerial vehicles or RAOVs, routine grade checks were performed using helicopters, resulting in less cost-effective solutions.

Our ROAV or drone inspection capabilities can be applied in a variety of situations such as:

• Torch on an offshore platform

• Pavement survey

• Slope

inspection • High-rise building inspection

Dyna O&M Sdn Bhd

Copyright © 2021 Dyna O&M Sdn Bhd. All rights reserved.

Social networks

- Dyna O&M Sdn Bhd

- Dyna O&M

- @DynaConsurv

Contact Details

- Bintulu Warehouse, No. 45, Lot 790, Block 20 Kemena Land District, 97000 Bintulu, Sarawak, Malaysia.

- +012 979 5854

- info@dyna-om.com